Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

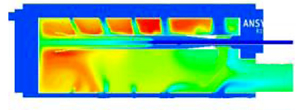

Numerical study of internal flue gas recirculation system applied to methane-hydrogen powered gas microturbine combustor

1

Faculty of Mechanical and Power Engineering, Department of Energy Conversion Engineering, Wroclaw University of Science and Technology, Poland

Submission date: 2022-05-09

Final revision date: 2022-07-11

Acceptance date: 2022-07-20

Online publication date: 2022-07-24

Publication date: 2023-01-02

Corresponding author

Jean-Marc Fąfara

Faculty of Mechanical and Power Engineering, Department of Energy Conversion Engineering, Wroclaw University of Science and Technology, Wybrzeże Wyspiańskiego, 50-370, Wrocław, Poland

Faculty of Mechanical and Power Engineering, Department of Energy Conversion Engineering, Wroclaw University of Science and Technology, Wybrzeże Wyspiańskiego, 50-370, Wrocław, Poland

Combustion Engines 2023,192(1), 63-77

KEYWORDS

TOPICS

ABSTRACT

Sources of renewable energy have been increasingly used all over the world. This kind of energy is highly desirable because of its unlimited availability. Unfortunately, renewable energy production very much depends on weather conditions. Consequently, it is necessary to store the produced excess energy in order to use it when needed. There is a technology able to produce a hydrogen/methane fuel from excess renewable energy, which may be stored. This technology is called the Power-to-Gas technology (P2G). Since the efficiency of this technological process depends on the hydrogen fraction in the renewable energy fuel, there is a need to increase this fraction. Concurrently, the gas microturbine technology is increasingly widely used in various industries (aviation, energy, automotive, military, etc). The P2G technology and the gas microturbine technology are likely to be integrated in the near future and, as mentioned above, the hydrogen fraction in the methane-hydrogen fuel will tend to increase. In order to power a gas microturbine with the methane-hydrogen fuel, it will be necessary to modify the combustor to avoid an excessive temperature increase and flashbacks. In this paper it is proposed to apply an autonomous internal exhaust gas recirculation system to resolve the hydrogen combustion problems indicated above. The operating principle and the proposed design of the recirculation system and the latter’s impact on the combustor’s operating parameters and emissivity (NOx and CO) are presented.

REFERENCES (44)

2.

Sterner M, Jentsch M, Holzhammer U. Energiewirtschaftliche und ökologische Bewertung eines Windgas-Angebotes. Fraunhofer Institute Raport. Kassel 2011.

3.

Fąfara J-M, Modliński NJ. Internal flue gas recirculation system in the gas microturbine as a way for the co-combustion of higher enriched hydrogen fuel. In: Kudela H, Cholewiński M, Machalski A. (Eds.). II edition of the XII Conference Young Scientists In Power Engineering – Book of abstracts. 153-154. Publishing House of the Wroclaw University of Science and Technology. Wroclaw 2020.

4.

Lav C, Kaul C, Singh R, Rai A. Potential of micro turbines for small scale power generation. Int J Adv Infor Sci Tech. 2013;2(5):35-39. https://doi.org/10.15693/ijais....

5.

Jerzak W. Adiabatic flame temperature and laminar burning velocity of CH4/H2/air mixtures. Archiwum Spalania. 2011; 11(3-4):197-206. https://www.researchgate.net/p....

6.

Güthe F, García M, Burdet A. Flue gas recirculation in gas turbine: Investigation of combustion reactivity and NOx emission. Proceedings of the ASME Turbo Expo. Orlando 8-12.06.2009. https://doi.org/10.1115/GT2009....

7.

Liu F, Guo H, Smallwood G. The chemical effect of CO2 replacement of N2 in air on the burning velocity of CH4 and H2 premixed flames. Combust Flame. 2003;133(4):495-497. https://doi.org/10.1016/S0010-....

8.

Ditaranto M, Li H, Løvås T. Concept of hydrogen fired gas turbine cycle with exhaust gas recirculation: Assessment of combustion and emissions performance. Int J Greenh Gas Con. 2015;(37):377-383. https://doi.org/10.1016/j.ijgg....

9.

Engineering ToolBox. Carbon Dioxide Gas – Specific Heat. 2005. https://www.engineeringtoolbox... (accessed on 28.06.2020).

10.

Engineering ToolBox. Water Vapor – Specific Heat. 2005. https://www.engineeringtoolbox... (accessed on 28.06.2020).

11.

Engineering ToolBox. Air – Specific Heat at Constant Pressure and Varying Temperature. 2004. https://www.engineeringtoolbox... (accessed on 28.06.2020).

12.

Gieras M. Miniaturowe silniki turboodrzutowe (Micro-turbojet engine). Publishing House of the Warsaw University of Technology. Warsaw 2016.

13.

Shi B, Hu J, Peng H, Ishizuka S. Effects of internal flue gas recirculation rate on the NOx emission in a methane/air premixed flame. Combust Flame. 2018;(188):199-211. https://doi.org/10.1016/j.comb....

14.

Jadidi M, Moghtadernejad S, Dolatabadi A. A comprehensive review on fluid dynamics and transport of suspension/liquid droplets and particles in high-velocity oxygen-fuel (HVOF) thermal spray. Coatings. 2015;5(4):576-645. https://doi.org/10.3390/coatin....

15.

Taamallah S, Vogiatzaki K, Alzahrani FM, Mokheimer EMA, Habib MA, Ghoniem AF. Fuel flexibility, stability and emissions in premixed hydrogen-rich gas turbine combustion: technology, fundamentals, and numerical simulations. Appl Energ. 2015;(154):1020-1047. https://doi.org/10.1016/j.apen....

16.

Wang L, Qi D, Sui X, Xie X. Analysis of re influence on MILD combustion of gas turbine. Energ Power Eng. 2013;(5):92-96. https://doi.org/10.4236/epe.20....

17.

Karpiński B, Szkodo M, Stąsiek J et al. High temperature air combustion. Energetyka. 2014;12(726):735-737.

18.

Mi J, Li P, Wang, F., Cheong K-P, Wang G. Review on MILD combustion of gaseous fuel: its definition, ignition, evolution, and emissions. Energ Fuel. 2021;35(9):7572-7607. https://doi.org/10.1021/acs.en....

19.

Mameri A, Tabet F, Aggab Y et al. MILD Combustion of hydrogenated biogas in opposed jet configuration. Proceedings of the 2nd International Workshop on CFD and Biomass Thermochemical Conversion. Leipzig 9.09.2016. https://www.researchgate.net/p....

20.

Webera W, Guptab AK, Mochidac S. High temperature air combustion (HiTAC): how it all started for applications in industrial furnaces and future prospects. Appl Energ. 2020; (278):115551. https://doi.org/10.1016/j.apen....

21.

Fortunato V, Giraldo A, Rouabah M, Nacereddine R, Delanaye M, Parente A. Experimental and numerical investigation of a MILD combustion chamber for micro gas turbine applications. Energies. 2018;11(12):3363. https://doi.org/10.3390/en1112....

22.

Albin T, Aguiar Da Franca A, Varea E et al. Potential and challenges of MILD combustion control for gas turbine applications. In: King R. (Eds.). Active Flow and Combustion Control – Notes on Numerical Fluid Mechanics and Multidisciplinary Design. 2015, 127. Springer.

24.

Gieras M, Stańkowski T. Computational study of an aerodynamic flow through a micro turbine engine combustor. J Power Technol. 2012;92(2):68-79.

25.

Suchocki T, Lampart P, Klonowicz P. Numerical investigation of a GTM 140 turbojet engine. Open Eng. 2015;(5): 478-484. https://doi.org/10.1515/eng-20....

26.

Dias FLG, Do Nascimento MAR, De Oliveira Rodrigues L. Reference area investigation in a gas turbine combustion chamber using CFD. J Mech Eng Autom. 2014;4(2):73-82. https://doi.org/10.5923/j.jmea....

27.

Vilag V, Vilag J, Carlanescu R, Mangra A, Florean F. CFD application for gas turbine combustion simulations. In: Ji G,, Zhu J. (Eds.). Computational Fluid Dynamics Simulations. IntechOpen. 2019. https://doi.org/10.5772/intech....

28.

Gonzalez C, Wong KC, Armfield S. Computational study of a micro turbine engine combustor using Large Eddy Simulation and Reynolds Averaged turbulence models. ANZIAM Journal. 2008;49(2007):407-422. https://doi.org/10.21914/anzia....

29.

Sosnowski M, Krzywanski J, Gnatowska R. Polyhedral meshing as an innovative approach to computational domain discretization of a cyclone in a fluidized bed CLC unit. E3S Web Conf. 2017;(14):01027. https://doi.org/10.1051/e3scon....

30.

Qureshi Z, Chan A. A study of the effect of element types on flow and turbulence characteristics around an isolated high-rise building. Eleventh International Conference on CFD in the Minerals and Process Industries. CSIRO. Melbourne 7-9.12.2015. https://www.cfd.com.au/cfd_con....

31.

Matyushenko A, Stabnikov A, Garbaruk A. Criteria of computational grid generation for turbulence models taking into account laminar-turbulent transition. J Phys: Conf Ser. 2019;(1400):077047. https://doi.org/10.1088/1742-6....

33.

Suchocki T, Lampart P, Surwiło J. Designation of operating characteristics for micro-jet engine and CFD validation. Mechanik. 2015;(7):813-820. https://doi.org/10.17814/mecha....

34.

Smith T, Shen Z, Friedman J. Evaluation of coefficients for the weighted sum of gray gases model. J Heat Transfer. 1982;104(4):602-608. https://doi.org/10.1115/1.3245....

35.

Fuchs F, Meidinger V, Neuburger N, Reiter T, Zündel M, Hupfer A. Challenges in designing very small jet engines fuel distribution and atomization. International Symposium on Transport Phenomena and Dynamics of Rotating Machinery. Honolulu 10-15.04.2016. https://hal.archives-ouvertes.....

37.

Smith GP, Golden DM, Frenklach M et al. Welcome to the GRI-Mech Home Page! http://www.me.berkeley.edu/gri... (accessed on 25.05. 2021).

38.

Ji C, Du W, Yang J, Wang S. A comprehensive study of light hydrocarbon mechanisms performance in predicting methane/hydrogen/air laminar burning velocities. Int J Hydrogen Energ. 2017;(42):17260-17274. https://doi.org/10.1016/j.ijhy....

39.

Launder BE, Spalding DB. The numerical computation of turbulent flows. Comput Method Appl M. 1974;3(2):269-289. https://doi.org/10.1016/0045-7....

41.

Air liquid. Gas encyclopedia – Méthane. 2021. https://encyclopedia.airliquid... (accessed on 19.06.2021).

42.

Air liquid. Gas encyclopedia – Hydrogène. 2021. https://encyclopedia.airliquid... (accessed on 19.06.2021).

43.

Air liquid. Gas encyclopedia – Oxygène. 2021. https://encyclopedia.airliquid... (accessed on 19.06.2021).

44.

PDF4PRO. AFC International, Inc. – Gas Detection&Air Monitoring Specialists – Combustibles. 2017. https://pdf4pro.com/view/combu... (accessed on 20.06.2021).

CITATIONS (2):

1.

Computational Fluid Dynamics (CFD) Assessment of the Internal Flue Gases Recirculation (IFGR) Applied to Gas Microturbine in the Context of More Hydrogen-Enriched Fuel Use

Jean-Marc Fąfara, Norbert Modliński

Energies

Jean-Marc Fąfara, Norbert Modliński

Energies

2.

Compressed air energy storage with T100 microturbines: Dynamic analysis and operational constraints

M. Raggio, M.L. Ferrari

Journal of Energy Storage

M. Raggio, M.L. Ferrari

Journal of Energy Storage

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.