Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Comparative analysis of waste-derived pyrolytic fuels applied in a contemporary compression ignition engine

1

Mechanical, Lublin University Of Technology, Poland

2

Mechanical, Bialystok University of Technology, Poland

3

Energy Technology, University of Vaasa, Finland

4

Mechanical, Rzeszow University of Technology, Poland

Submission date: 2023-11-10

Final revision date: 2024-03-04

Acceptance date: 2024-04-02

Online publication date: 2024-06-27

Publication date: 2024-08-09

Corresponding author

Arkadiusz Rybak

Mechanical, Lublin University Of Technology, Nadbystrzycka 38D, 20-618, Lublin, Poland

Mechanical, Lublin University Of Technology, Nadbystrzycka 38D, 20-618, Lublin, Poland

Combustion Engines 2024,198(3), 74-81

KEYWORDS

TOPICS

ABSTRACT

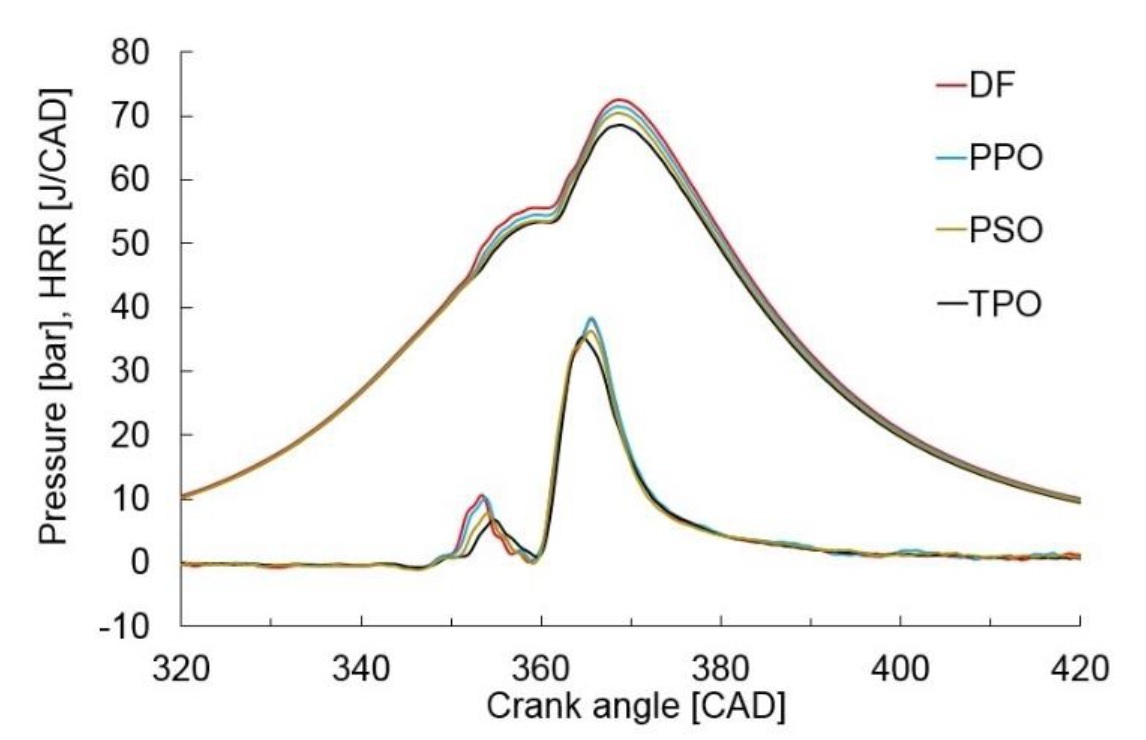

This article presents the outcomes of research regarding pyrolysis oils obtained from waste sources (WPO) used to power a compression-ignition engine. Oils obtained in an industrial process based on polypropylene (PPO), polystyrene (PSO) and used car tires (TPO) were used. Prior to conducting engine tests, a in-depth examination of the tested fuels parameters was undertaken. For the tests was used an advanced single-cylinder research engine utilizing split fuel injection technique. Emission analysis was performed using multi-compound FTIR analytical system. The WPO were blended with diesel fuel in proportions of 20%, on the mass basis and tested at middle engine load and variable EGR rates. Tests have shown that modern combustion systems compliant with the Tier 4 standard with multi-pulse injection can handle fuels with a WPO content of 20% without the need for recalibration. The addition of PPO did not significantly affect the emission, while mixing with PSO resulted in elevated levels of hydrocarbon and carbon monoxide emissions. Regarding to the mixture with TPO, increased levels of particulate matter, sulfur oxides, aromatic compounds and formic acid were observed.

REFERENCES (26)

1.

Alawa B, Chakma S. Investigation in compression ignition engine performance using alternative fuels produced from waste packaging materials. Resour Conserv Recy Adv. 2022;14:200075. https://doi.org/10.1016/j.rcra....

2.

Aydin H, Ilkiliç C. Optimization of fuel production from waste vehicle tires by pyrolysis and resembling to diesel fuel by various desulfurization methods. Fuel. 2012;102:605-612. https://doi.org/10.1016/j.fuel....

3.

Bae C, Kim J. Alternative fuels for internal combustion engines. P Combust Inst. 2017;36(3):3389-3413. https://doi.org/10.1016/j.proc....

4.

Cunliffe AM, Williams PT. Composition of oils derived from the batch pyrolysis of tyres. J Anal Appl Pyrol. 1998;44(2):131-152. https://doi.org/10.1016/S0165-....

5.

Czajczyńska D, Krzyżańska R, Jouhara H, Spencer N. Use of pyrolytic gas from waste tire as a fuel: a review. Energy. 2017;134:1121-1131. https://doi.org/10.1016/j.ener....

6.

Energy demand: three drivers | ExxonMobil. https://corporate.exxonmobil.c... (accessed on Jan. 06, 2022).

8.

González JF, Encinar JM, Canito JL, Rodríguez JJ. Pyrolysis of automobile tyre waste. Influence of operating variables and kinetics study. J Anal Appl Pyrol. 2001;58-59(59):667-683. https://doi.org/10.1016/S0165-....

9.

Grigiante M, Ischia M, Baratieri M, Dal Maschio R, Ragazzi M. Pyrolysis analysis and solid residue stabilization of polymers, waste tyres, spruce sawdust and sewage sludge. Waste Biomass Valor. 2010;1:381-393. https://doi.org/10.1007/s12649....

10.

Han J, Li W, Liu D, Qin L, Chen W, Xing F. Pyrolysis characteristic and mechanism of waste tyre: a thermogravimetry-mass spectrometry analysis. J Anal Appl Pyrol. 2018;129:1-5. https://doi.org/10.1016/j.jaap....

11.

Ilkiliç C, Aydin H. Fuel production from waste vehicle tires by catalytic pyrolysis and its application in a diesel engine. Fuel Process Technol. 2011;92(5):1129-1135. https://doi.org/10.1016/j.fupr....

12.

Januszewicz K, Hunicz J, Kazimierski P, Rybak A, Suchocki T, Duda K et al. experimental assessment on a diesel engine powered by blends of waste-plastic-derived pyrolysis oil with diesel. Energy. 2023;281:128330. https://doi.org/10.1016/j.ener....

13.

Kline S, McClintock F. Describing uncertainty in single sample experiments. Mech Engineering. 1953;75:3-8.

14.

Mangesh VL, Padmanabhan S, Tamizhdurai P, Ramesh A. Experimental investigation to identify the type of waste plastic pyrolysis oil suitable for conversion to diesel engine fuel. J Clean Prod. 2020;246:119066. https://doi.org/10.1016/j.jcle....

15.

Mikulski M, Ambrosewicz-Walacik M, Hunicz J, Nitkiewicz S. Combustion engine applications of waste tyre pyrolytic oil. Prog Energ Combust. 2021;85:100915. https://doi.org/10.1016/j.pecs....

16.

Mikulski M, Hunicz J, Duda K, Kazimierski P, Suchocki T, Rybak A. Tyre pyrolytic oil fuel blends in a modern compression ignition engine: a comprehensive combustion and emissions analysis. Fuel. 2022;320:123869. https://doi.org/10.1016/j.fuel....

17.

Murugan S, Ramaswamy MC, Nagarajan G. A comparative study on the performance, emission and combustion studies of a DI diesel engine using distilled tyre pyrolysis oil-diesel blends. Fuel. 2008;87(10-11):2111-2121. https://doi.org/10.1016/j.fuel....

18.

Pakdel H, Pantea DM, Roy C. Production of dl-limonene by vacuum pyrolysis of used tires. J Anal Appl Pyrol. 2001;57(1):91-107. https://doi.org/10.1016/S0165-....

19.

Roosen M, Mys N, Kusenberg M, Billen P, Dumoulin A, Dewulf J et al. Detailed analysis of the composition of selected plastic packaging waste products and its implications for mechanical and thermochemical recycling. Environ Sci Technol. 2020;54(20):13282-13293. https://doi.org/10.1021/acs.es....

20.

Sienkiewicz M, Janik H, Borzędowska-Labuda K, Kucińska-Lipka J. Environmentally friendly polymer-rubber composites obtained from waste tyres: a review. J Clean Prod. 2017;147:560-571. https://doi.org/10.1016/j.jcle....

21.

Sienkiewicz M, Kucinska-Lipka J, Janik H, Balas A. Progress in used tyres management in the European Union: a review. Waste Manage. 2012;32(10):1742-1751. https://doi.org/10.1016/j.wasm....

22.

Sikora M, Orliński P. Hydrotreated vegetable oil fuel within the Fit for 55 package. Combustion Engines. 2023. https://doi.org/10.19206/CE-17....

23.

Szwaja M, Szymanek A. Combustion comparative analysis of pyrolysis oil and diesel fuel under constant-volume conditions. Combustion Engines. 2023;195(4):90-96. https://doi.org/10.19206/CE-16....

24.

Torretta V, Rada EC, Ragazzi M, Trulli E, Istrate IA, Cioca LI. Treatment and disposal of tyres: two EU approaches. A review. Waste Manage. 2015;45:152-160. https://doi.org/10.1016/j.wasm....

25.

Yaqoob H, Teoh YH, Jamil MA, Gulzar M. Potential of tire pyrolysis oil as an alternate fuel for diesel engines: a review. J Energy Inst. 2021;96:205-221. https://doi.org/10.1016/j.joei....

26.

Zhang Z, Lohr L, Escalante C, Wetzstein M. Food versus fuel: what do prices tell us? Energ Policy. 2010;38(1):445-451. https://doi.org/10.1016/j.enpo....

CITATIONS (3):

1.

TRANSBALTICA XV: Transportation Science and Technology

Jonas Matijošius, Yurii Gutarevych, Dmitrij Trifonov, Yevhenii Shuba, Oleksander Syrota, Olena Samar, Pavlo Marchenko, Alfredas Rimkus

Jonas Matijošius, Yurii Gutarevych, Dmitrij Trifonov, Yevhenii Shuba, Oleksander Syrota, Olena Samar, Pavlo Marchenko, Alfredas Rimkus

2.

Cycle-by-cycle performance evaluation of a diesel engine fueled with a mixture of hydrotreated vegetable oil mixed with waste plastic pyrolysis oils

Dariusz Szpica, Michał S. Gęca, Jacek Hunicz, Mirosław Jakubowski, Artur Krzemiński, Grzegorz Mieczkowski

Combustion Engines

Dariusz Szpica, Michał S. Gęca, Jacek Hunicz, Mirosław Jakubowski, Artur Krzemiński, Grzegorz Mieczkowski

Combustion Engines

3.

Problems of filtration and standardization on parameter conformity of diesel fuels containing decarbonization components and processing impurities

Paweł Woś, Artur Krzemiński, Hubert Kuszewski, Mirosław Jakubowski, Artur JAWORSKI, Jacek Hunicz, Arkadiusz Rybak, Andrzej Borawski, Dariusz Szpica

Combustion Engines

Paweł Woś, Artur Krzemiński, Hubert Kuszewski, Mirosław Jakubowski, Artur JAWORSKI, Jacek Hunicz, Arkadiusz Rybak, Andrzej Borawski, Dariusz Szpica

Combustion Engines

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.