Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Influence of engine load on piston ring pack operation of an automotive IC engine

1

Faculty of Transport, Warsaw University of Technology, Poland

2

Faculty of Mechanical Engineering, Lublin University of Technology, Poland

Submission date: 2021-09-06

Final revision date: 2021-12-15

Acceptance date: 2021-12-20

Online publication date: 2022-02-14

Publication date: 2022-07-06

Corresponding author

Combustion Engines 2022,190(3), 88-94

KEYWORDS

TOPICS

ABSTRACT

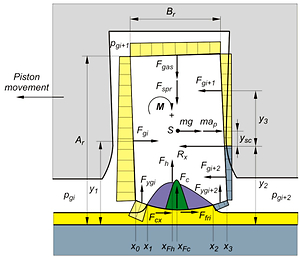

A piston-rings-cylinder (PRC) assembly determines the blowby, engine oil consumption, and friction and wear processes accompanying the system's operation. Thus, it is crucial for the whole IC engine efficiency and lifetime. A lot of research effort is put into increasing the performance of this complex and highly dynamic system. Advanced, comprehensive models play an important role in understanding and improving the PRC system.

In the presented work, the effect of load on the operation of the ring pack of an automotive gasoline engine is analyzed. A comprehensive model that covers the gas flow through the crevices of the PRC system, ring displacements in the groove, and ring lubrication was used for this analysis. The results of the simulations show that the local thickness of the oil film, especially near the piston top dead center is compared to the height of the combined surface roughness of a cylinder liner and piston rings, and friction-related asperity contact strongly increases as the engine load increases. The simulations also show that the engine load affects the axial displacements of the rings in the grooves but practically does not affect the thickness of the oil film left by the ring pack on the cylinder liner.

REFERENCES (21)

1.

BOLANDER, N.W., STEENWYK, B.D., SADEGHI, F. et al. Lubrication regime transitions at the piston ring - cylinder liner interface. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology. 2005, 219, 19-31. https://doi.org/10.1243/135065....

2.

DOWSON, D. Piston assemblies: background and lubrication analysis. Engine Tribology. Elsevier, Amsterdam 1993. https://doi.org/10.1016/S0167-....

3.

GREENWOOD, J., TRIPP, J.H. The contact of two nominally flat rough surfaces. Proceedings of the Institution of Mechanical Engineers. 1971, 185, 625-633. https://doi.org/10.1243/PIME_P....

4.

GULWADI, S.D. Analysis of tribological performance of a piston ring pack. Tribology Transactions. 2000, 43(2), 151-162. https://doi.org/10.1080/104020....

6.

HOLMBERG, K., ERDEMIR, A. The impact of tribology on energy use and CO2 emission globally and in combustion engine and electric cars. Tribology International. 2019, 135, 389-396. https://doi.org/10.1016/j.trib....

7.

KNOLL, G., PEEKEN, H., LECHTAPE-GRÜTER, R. et al. Computer-aided simulation of piston and piston ring dynamics. Journal of Engineering for Gas Turbines and Power. 1996, 118, 880-886. https://doi.org/10.1115/1.2817....

8.

KOSZAŁKA, G., HUNICZ, J. Comparative study of energy losses related to the ring pack operation in homogeneous charge compression ignition and spark ignition combustion. Energy. 2021, 235, 121388. https://doi.org/10.1016/j.ener....

9.

KOSZAŁKA, G., NIEWCZAS, A., GUZIK, M. Predicted and actual effect of cylinder liner wear on the blowby in a truck diesel engine. SAE Technical Paper 2008-01-1717. 2008. https://doi.org/10.4271/2008-0....

10.

KOSZAŁKA, G. Application of the piston-rings-cylinder kit model in the evaluation of operational changes in blowby flow rate. Eksploatacja i Niezawodność – Maintenance and Reliability. 2010, 4, 72-81.

11.

KOSZAŁKA, G., GUZIK, M. Mathematical model of piston ring sealing in combustion engine. Polish Maritime Research. 2014, 4(84), 66-78. https://doi.org/10.2478/pomr-2....

12.

PATIR, N., CHENG, H.S. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. Journal of Tribology. 1978, 100(1), 12-17. https://doi.org/10.1115/1.3453....

13.

PATIR, N., CHENG, H.S. Application of average flow model to lubrication between rough sliding surfaces. Journal of Tribology. 1979, 101(2), 220-229. https://doi.org/10.1115/1.3453....

14.

TIAN, T. Dynamic behaviors of piston rings and their practical impact-part ii: oil transport, friction, and wear of ring/liner interface and the effects of piston and ring dynamics. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology. 2002, 216, 229-247. https://doi.org/10.1243/135065....

15.

WOLFF, A. Experimental verification of the model of piston ring pack operation of an internal combustion engine. The Archive of Mechanical Engineering. 2009, 56(1), 73-90. https://doi.org/10.24425/ame.2....

16.

WOLFF, A. Influence of engine load on piston ring pack operation of a marine two-stroke engine. Journal of KONES Powertrain and Transport. 2012, 19(2), 557-569. https://doi.org/10.5604/123140....

17.

WOLFF, A. Simulation based study of the system piston-ring-cylinder of a marine two-stroke engine. Tribology Transactions. 2014, 57(4), 653-667. https://doi.org/10.1080/104020....

18.

WOLFF, A. Influence of sliding surface roughness and oil temperature on piston ring pack operation of an automotive IC engine. IOP Conference Series: Materials Science and Engineering. 2016, 148, 1-10. https://doi.org/10.1088/1757-8....

19.

WOLFF, A. Numerical analysis of gas flow through the labyrinth seal of piston rings of an automotive IC engine. IOP Conference Series: Materials Science and Engineering. 2018, 421, 1-11. https://doi.org/10.1088/1757-8....

20.

WOLFF, A. Influence of piston ring profiles and oil temperature distribution on cylinder liner lubrication of a marine two-stroke engine. Combustion Engines. 2019, 178(3), 257-263. https://doi.org/10.19206/CE-20....

21.

WOLFF, A. Numerical analysis of the system piston-ring-cylinder of an automotive IC engine. SAE Technical Paper 2020-01-2160, 2020. https://doi.org/10.4271/2020-0....

CITATIONS (4):

1.

Analysis of jatropha oil-kerosene fuel mixtures on the performance of a variable-load direct injection CI engine

Robinson Ejilah, Abiodun Ogbaneme, Osazoduwa Agboneni, Sikiru Adekunle

Combustion Engines

Robinson Ejilah, Abiodun Ogbaneme, Osazoduwa Agboneni, Sikiru Adekunle

Combustion Engines

2.

Analysis of lubricating oil degradation and its influence on brake specific fuel consumption of a light-duty compression-ignition engine running a durability cycle on a test stand

Rafał Sala, Kamil Węglarz, Andrzej Suchecki

Combustion Engines

Rafał Sala, Kamil Węglarz, Andrzej Suchecki

Combustion Engines

3.

Determination of the Temperature on the Inner Wall of the Piston Machine Body by Solving the Inverse Problem

Magda Joachimiak, Andrzej Frąckowiak, Damian Joachimiak

Heat Transfer Engineering

Magda Joachimiak, Andrzej Frąckowiak, Damian Joachimiak

Heat Transfer Engineering

4.

Tribological Analysis of Manganese Phosphate Coating on Steel Pistons for Internal Combustion Engines

Paweł Żurawski, Andrzej Trytek

Key Engineering Materials

Paweł Żurawski, Andrzej Trytek

Key Engineering Materials

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.