Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

An analytical study on the performance of spark-ignition engines operating with ammonia fuel

1

Department of Engine Machinery, University of Transport and Communications, Ha Noi, Viet Nam

2

Department of Internal Combustion Engine, Le Quy Don Technical University, Ha Noi, Viet Nam

These authors had equal contribution to this work

Submission date: 2025-07-10

Final revision date: 2026-01-05

Acceptance date: 2026-01-06

Online publication date: 2026-01-24

Corresponding author

Quynh Nguyen Thin

Department of Engine Machinery, University of Transport and Communications, Ha Noi, Viet Nam

Department of Engine Machinery, University of Transport and Communications, Ha Noi, Viet Nam

KEYWORDS

TOPICS

ABSTRACT

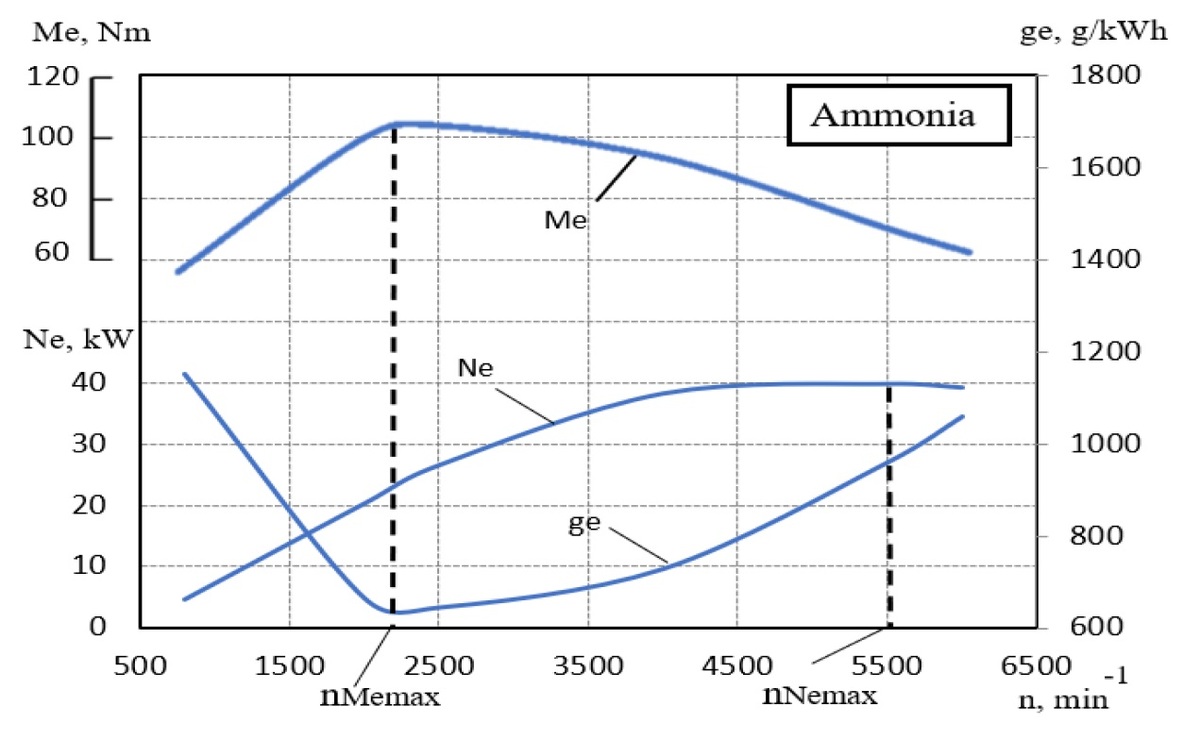

Ammonia is a promising fuel due to its low cost, carbon-free energy carrier, renewable hydrogen carrier, scalability and flexibility, global availability, and long-term energy storage. It can be synthesized from renewable energy sources and used as a carbon-free fuel in internal combustion engines. When ammonia is completely burned, due to the relatively low combustion temperature of the ammonia-air mixture and the absence of carbon in the molecule, the only toxic emissions are nitrogen oxides. These nitrogen oxide emissions can be effectively reduced by the Selective Catalytic Reduction technology, in which ammonia acts as a reductant in the Selective Catalytic Reduction system. This study presents the characteristics of a spark-ignition internal combustion engine 4CH 7.6/7 powered by ammonia fuel. The results show that the maximum brake torque on the wide-open throttle operating characteristics increases by 6.1 %, while the maximum brake power decreases by 30 %, and the brake-specific ammonia fuel consumption is almost 2 times higher than that of gasoline at the same engine power. Moreover, with a research octane number of ammonia up to 110, it will help improve anti-knock properties. Along with that, increasing the compression ratio and using turbochargers can be considered to improve engine performance.

REFERENCES (14)

1.

Briceno-Mena LA, Venugopalan G, Romagnoli JA, Arges CG. Machine learning for guiding high-temperature PEM fuel cells with greater power density. Patterns. 2021;2(2). https://doi.org/10.1016/j.patt....

2.

Cardoso JS, Silva V, Rocha RC, Hall MJ, Costa M, Eusébio D. Ammonia as an energy vector: current and future prospects for low-carbon fuel applications in internal combustion engines. J Clean Prod. 2021;296:1256562. https://doi.org/10.1016/j.jcle....

3.

Cheng Q, Muhammad A, Kaario O, Ahmad Z, Martti L. Ammonia as a sustainable fuel: review and novel strategies. Renew Sustain Energy Rev. 2025;207:114995. https://doi.org/10.1016/j.rser....

4.

Douaud AM, Eyzat P. Four-octane-number method for predicting the anti-knock behavior of fuels and engines. SAE Technical Paper 780080. 1978. https://doi.org/10.4271/780080.

5.

Dunin AY, Nguyen Thin Quynh, Golubkov LN, Computa-tional study of the effect of increasing the fuel injection pressure up to 3000 bar on the performance of the diesel engine and its gaseous emissions. International Conference on Engineering Management of Communication and Technology (EMCTECH). 2020:65-70. https://doi.org/10.1109/EMCTEC....

6.

Giddey S, Badwal SPS, Munnings C, Dolan M. Ammonia as a renewable energy transportation media. ACS Sustainable Chem Eng. 2017;5(11):10231-10239. https://doi.org/10.1021/acssus....

7.

Hong C, Ji C, Wang S, Xin G, Wang Z, Meng H et al. An experimental study of various load control strategies for an ammonia/hydrogen dual-fuel engine with the Miller cycle. Fuel Proc Technol. 2023;247:107780. https://doi.org/10.1016/j.fupr....

8.

Huang Z. Fuel blend combustion for decarbonization. Proc Combust Inst. 2024;40(1-4). https://doi.org/10.1016/j.proc....

9.

Kuta K, Nadimi E, Przybyła G, Żmudka Z, Adamczyk W. Ammonia CI engine aftertreatment systems design and flow simulation. Combustion Engines. 2022;190(3):3-10. https://doi.org/10.19206/CE-14....

10.

Kim K, Roh G, Kim W, Chun K. A preliminary study on an alternative ship propulsion system fueled by ammonia: environmental and economic assessments. J Mar Sci Eng. 2020;8(3). https://doi.org/10.3390/jmse80....

11.

MacFarlane DR, Cherepanov PV, Choi J, Suryanto BHR, Hodgetts RY, Bakker JM et al. A roadmap to the ammonia economy. Joule. 2020;4(6):1186-1205. https://doi.org/10.1016/j.joul....

12.

Stępień Z. Ammonia as an alternative fuel to internal combustion engines. Combustion Engines. 2025;200(1):117-127. https://doi.org/10.19206/CE-20....

13.

Thin Quynh N, Duc Le H, Dunin, A. Influences of injector geometry parameters on fuel injection characteristics and parameters of a diesel engine. Transport and Communications Science Journal. 2023;74(4):530-543. https://doi.org/10.47869/tcsj.....

14.

Valera-Medina A, Xiao H, Owen-Jones M, David WIF, Bowen PJ. Ammonia for power. Prog Energy Combust Sci. 2018;69:63-102. https://doi.org/10.1016/j.pecs....

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.