Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Numerical analysis of the front deflector at the outer air seal of low-pressure turbine

1

Faculty of Mechanical Engineering and Aeronautics, Rzeszow University of Technology, Poland

2

Aerodynamics and Numerical Methods, MTU Aero Engines Polska, Poland

Submission date: 2025-11-15

Final revision date: 2026-01-18

Acceptance date: 2026-02-05

Online publication date: 2026-02-12

Corresponding author

Kacper Palkus

Faculty of Mechanical Engineering and Aeronautics, Rzeszow University of Technology, Aleja Powstańców Warszawy 12, 35-959, Rzeszów, Poland

Faculty of Mechanical Engineering and Aeronautics, Rzeszow University of Technology, Aleja Powstańców Warszawy 12, 35-959, Rzeszów, Poland

KEYWORDS

TOPICS

ABSTRACT

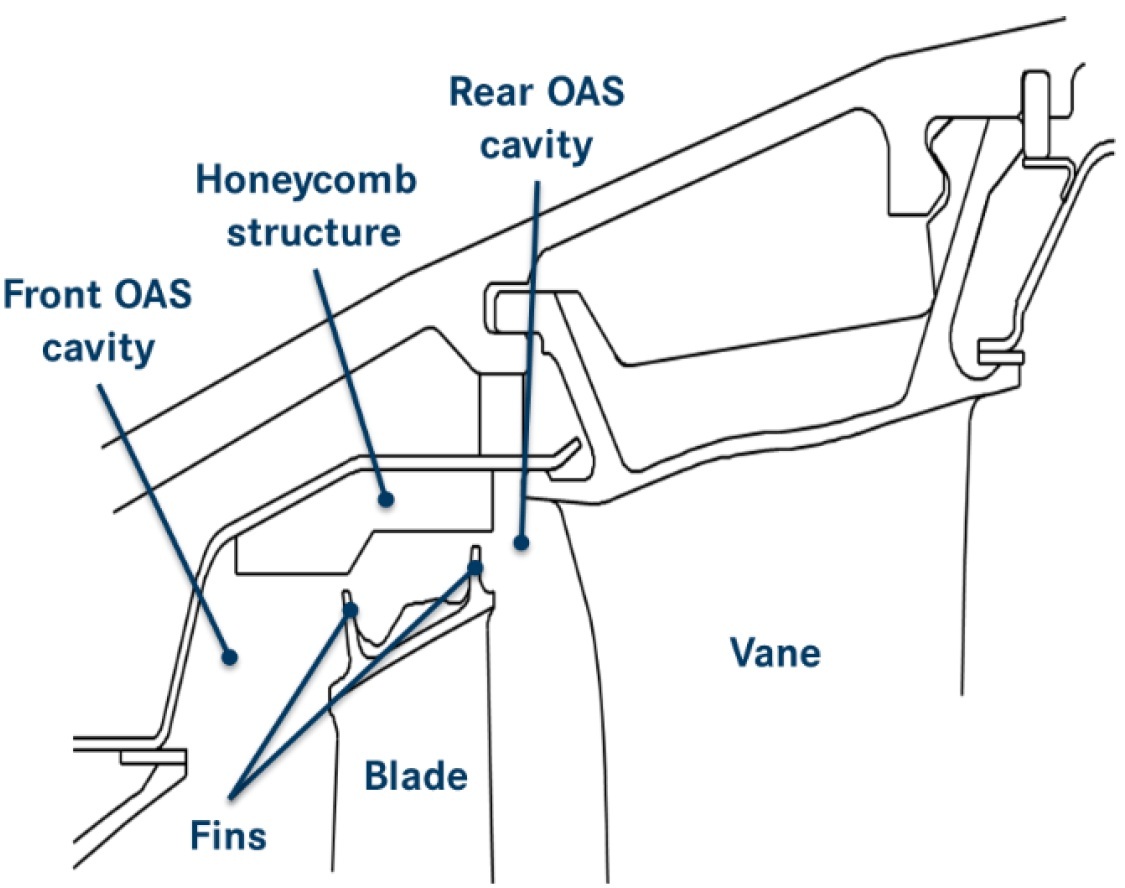

A new design solution – the front deflector – intended to improve the performance of the outer air seals of the low-pressure turbine is analyzed in this paper using steady Reynolds-Averaged Navier-Stokes (RANS) simulations of a three-stage, state-of-the-art LPT model, including inner and outer cavities. The regions near the casing in the LPT still show potential for improvement, mainly due to flow interactions associated with the outer air seals. One recent concept for improving these areas is the front deflector. The solution is to modify the front part of the cavity. Its operating principle is to introduce an additional labyrinth for the leakage while simultaneously minimizing the front cavity volume. In the paper, several scenarios for implementing this feature are analyzed, including reducing the front-cavity volume without a static fin and adding a static fin to create an auxiliary labyrinth. Furthermore, the effects on the flow and the potential improvements in LPT efficiency associated with the solution are discussed. The former reduces front-cavity recirculation and its interaction with the mainstream; the latter reduces seal leakage when the fin length is sufficient. Across three stages, the predicted changes in LPT isentropic efficiency are on the order of 0.03–0.06%, depending on the scenario.

REFERENCES (28)

1.

Albada van GD, Leer van B, Roberts W. A comparative study of computational methods in cosmic gas dynamics. Astron Astrophys. 1982;108(1):76-84. https://ui.adsabs.harvard.edu/....

2.

Brush seals: World-class sealing technology. MTU Aero Engines. 2014. Report No. EN10/20/MUC/00500/AD/RI/D.

3.

Chupp RE, Hendricks RC, Lattime SB, Steinetz BM. Sealing in turbomachinery. NASA, Glenn Research Center, Cleveland, USA, NASA Technical Memo. NASA/TM-2006-214341. 2006.

4.

Dewanji D, Rao AG, van Buijtenen JP. Conceptual study of future aero-engine concepts. Int J Turbo Jet Engines. 2010;26(4):263-276. https://doi.org/10.1515/TJJ.20....

5.

Fanelli JJA, Bassery JJA, Dupeyre RJP, Francois EL. Aube mobile pour une roue d’une turbomachine. Applicant: Safran Aircraft Engines. Patent No. FR3092864A1. 2020.

6.

Flitney RK. Seals and sealing handbook. Ed 6th. Butterworth-Heinemann. 2007. https://doi.org/10.1016/B978-0....

7.

Franke M, Kugeler E, Nurnberger D. Das DLR-Verfahren TRACE: Moderne Simulationstechniken für Turbomaschinenströmungen. In: DGLR-Jahrbuch. Deutscher Luft- und Raumfahrtkongre; 2005 Sep 26-29.

8.

Giboni A, Wolter K, Menter JR, Pfost H. Experimental and numerical investigation into the unsteady interaction of labyrinth seal leakage flow and main flow in a 1.5-stage axial turbine. Proceedings of ASME Turbo Expo 2004; 2004 Jun 14–17; Vienna. https://doi.org/10.1115/GT2004....

9.

Gier J, Stubert B, Brouillet B, de Vito L. Interaction of shroud leakage flow and main flow in a three-stage LPT. J Turbomach. 2005;127(4):649-658. https://doi.org/10.1115/1.2006....

10.

Hendricks RC, Chupp RE, Lattime SB, Steinetz BM. Turbomachine interface sealing. NASA Technical Memorandum NASA/TM – 2005-213633. 2005.

11.

Henke M, Wein L, Kluge T, Guendogdu Y, Biester MH, Seume JR. Experimental and numerical verification of the core-flow in a new low-pressure turbine. Proceedings of ASME Turbo Expo 2016; 2016 Jun 13-17; Seoul. ASME. https://doi.org/10.1115/GT2016....

13.

Kato M, Launder BE. The modeling of turbulent flow around stationary and vibrating square cylinders. 9th Symposium on Turbulent Shear Flows. Kyoto 1993. https://api.semanticscholar.or....

14.

Klingels H. Sealing system for a turbomachine and axial flow turbomachine. Patent EP3324002B1. 2021.

15.

Mahle I. Improving the interaction between leakage flows and main flow in a low pressure turbine. ASME. 2010;GT2010-22448:1177-1186. https://doi.org/10.1115/GT2010....

16.

Mahle I, Schmierer R. Inverse fin arrangement in a low pressure turbine to improve the interaction between shroud leakage flows and main flow. ASME. 2010;GT2010-22448:1177-1186. https://doi.org/10.1115/GT2011....

17.

NASA Conference, Seal/Secondary Air System Workshop. NASA/CP-2009-215677. 2008:131-193.

18.

Nishii D, Hamabe M. Secondary flow suppression structure. Patent WO2021199718A1. 2004.

19.

Pałkus K. Low pressure turbine efficiency increase by developing new concept of outer air seal. Doctoral Thesis 2024.

20.

Pałkus K, Lauer C, Schmierer R. Axial turbomachine sealing system. Patent EP3822461A1. 2021.

21.

Pałkus K, Strzelczyk PM. Dimensionless numbers relationships for outer air seal of low pressure turbine. Int J Turbomach Propuls Power. 2021;6(3):33. https://doi.org/10.3390/ijtpp6....

22.

Pfau A, Schlienger J, Rusch D, Kalfas AI, Abhari RS. Unsteady flow interactions within the inlet cavity of a turbine rotor tip labyrinth seal. J Turbomach. 2005;127(4):679-688. https://doi.org/10.1115/1.2008....

23.

Rosic B, Denton JD, Curtis EM, Peterson AT. The influence of shroud and cavity geometry on turbine performance: an experimental and computational study – part I and II. J Turbomach. 2008;130(4):041002. https://doi.org/10.1115/1.2777....

24.

Vanhaelst R, Bannack C, Klose M. Comparison of two measurement methods for the determination of extended turbine maps at the eATL test bench of the Ostfalia UAS. Combustion Engines. 2017;169(2):43‑48. https://doi.org/10.19206/CE-20....

25.

Wein L. Large-Eddy-Simulation von Deckband labyrinthdichtungen [dissertation]. Hannover: Leibniz University Hannover 2020. https://doi.org/ 10.15488/10202.

26.

Wein L, Kluge T, Seume JR, Hain R, Fuchs T, Kahler C et al. Validation of RANS turbulence models for labyrinth seal flows by means of particle image velocimetry. Proceedings of ASME Turbo Expo 2020; 2020 Sep 21–25. https://doi.org/10.1115/GT2020....

28.

Yang H, Nuernberger D, Kersken H. Toward excellence in turbomachinery computational fluid dynamics: a hybrid structured-unstructured Reynolds-Averaged Navier–Stokes solver. J Turbomach. 2006;128(2):390-402. https://doi.org/10.1115/1.2162....

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.