Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Optimisation-oriented verification of a plain bearing process model taking into account actual tolerances and measurement accuracy

1

Department of Mechatronics, University of Warmia and Mazury in Olsztyn, Poland

2

Chair of Vehicles and Machinery Exploitation, University of Warmia and Mazury in Olsztyn, Poland

Submission date: 2025-05-12

Final revision date: 2025-06-25

Acceptance date: 2025-06-27

Online publication date: 2025-07-16

Publication date: 2025-11-14

Corresponding author

Daria Skonieczna

Chair of Vehicles and Machinery Exploitation, University of Warmia and Mazury in Olsztyn, Oczapowskiego 11, 11-041 Olsztyn, Olsztyn, Poland

Chair of Vehicles and Machinery Exploitation, University of Warmia and Mazury in Olsztyn, Oczapowskiego 11, 11-041 Olsztyn, Olsztyn, Poland

Combustion Engines 2025,203(4), 67-75

KEYWORDS

TOPICS

ABSTRACT

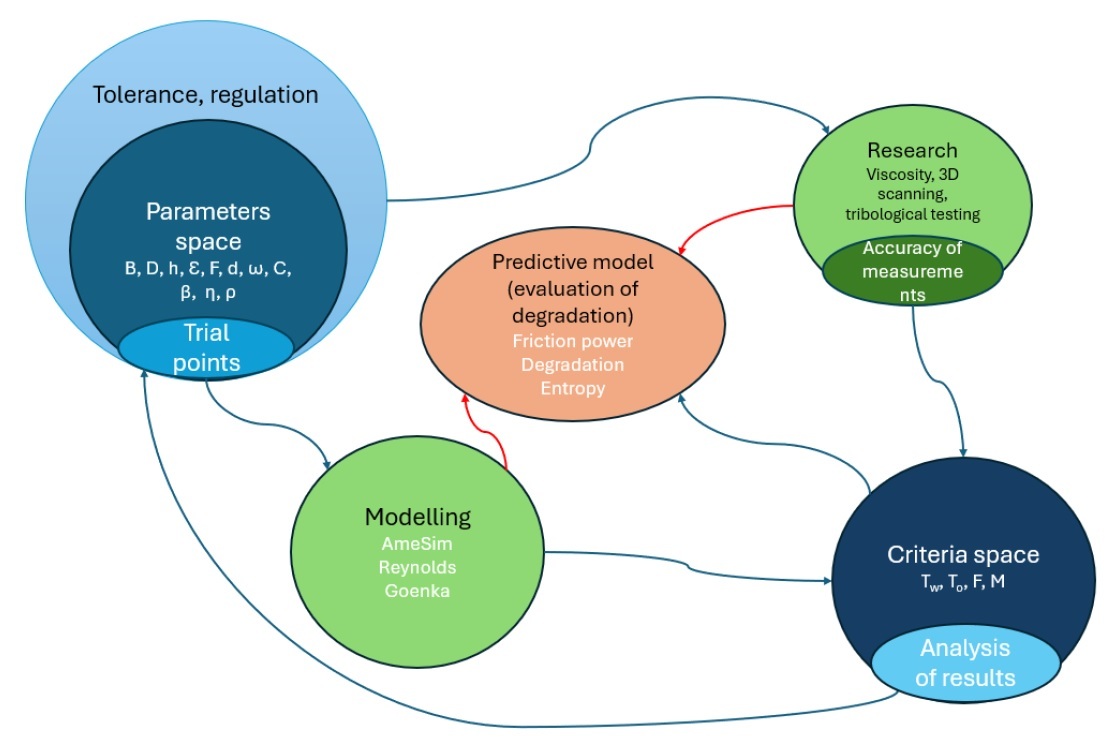

This paper presents a methodology for verifying a numerical model of the plain bearing test process used to evaluate the characteristics of internal combustion engine components, in particular camshaft bearings. The developed approach is based on the use of optimisation methods under parametric uncertainty, which makes it possible to take into account the actual spread of technological and operational parameters.

The study uses a test rig that reflects the operating conditions of a bearing in an internal combustion engine, including a load simulated with an eccentric. SAE 15W40 grade oil, typical for engine lubrication systems, was used as the lubricant. The input parameter space includes geometrical features of the bearing (diameter, width, clearance, eccentric), initial load force, shaft speed and rheological properties of the oil.

The proposed approach to verification does not involve a direct comparison of computational and experimental data, but rather a search for the most probable solution within given tolerance limits and taking into account the measurement accuracy of the selected characteristics. The verification criteria are the measured values of oil and bearing surface temperature, load force and friction torque in the oil film. Measurement uncertainty is also taken into account in the optimisation process.

The developed methodology makes it possible not only to assess the reliability of the numerical model, but also to analyse the sensitivity of the model to parameter variability and to determine the robustness of the friction node under study.

REFERENCES (17)

1.

Asmussen S, Glynn PW. Stochastic simulation: algorithms and analysis. Springer 2007.

3.

Ding H, Mermertas Ü, Hagemann T, Schwarze H. Calculation and validation of planet gear sliding bearings for a three-stage wind turbine gearbox. Lubricants. 2024;12(3):95. https://doi.org/10.3390/lubric....

4.

Du F, Li D, Hao M, Yu Y, Wang W. Simulation and experimental research on the failure of marine sliding bearings. J. Mar. Sci. Eng. 2023;11(1):61. https://doi.org/10.3390/jmse11....

5.

Fernández MM, Rüth L, Sauer B. Comparative study of a simulative bearing design with an experimentally determined data of a prototype bearing. Forsch Ingenieurwes. 2021;85:1015-1027. https://doi.org/10.1007/s10010....

6.

Goenka PK. Analytical curve fits for solution parameters of dynamically loaded journal bearings. ASME J Tribol. 1984;106(3):421-427.

7.

Goto M, Inoue T, Heya A, Katayama K, Kimura S, Tomimatsu SE et al. Modeling of journal bearings for wear diagnosis and its verification using SVM. 4th Asia Pac Conf Progn Health Manag. 2023. https://doi.org/10.36001/phmap....

8.

Hamrock BJ, Schmid SR, Jacobson BO. Fundamentals of fluid film lubrication. Boca Raton 2004. eISBN 9780429215315. https://doi.org/10.1201/978020....

9.

König F, Sous C, Jacobs G. Numerical prediction of the frictional losses in sliding bearings during start-stop operation. Friction. 2020;9(12):583-597. https://doi.org/10.1007/s40544....

10.

Kumar A, Goenka PK, Booker JF. Modal analysis of elastohydrodynamic lubrication: a connecting rod application. J Tribol. 1990;112(3):537-544.

11.

Machado T, Cavalca KL. Experimental validation of a bearing wear model using the directional response of the rotor-bearing system. An Acad Bras Ciênc. 2016;88(4). https://doi.org/10.1590/0001-3....

12.

Montgomery DC. Design and analysis of experiments. Wiley. 2017. ISBN 1119299365, 9781119299363.

13.

Panara D, Pivetta V, Shoup T, Baldassarre L. Numerical models and experimental validation of high speed, high load, hydrodynamic bearings. Turbomach Lab Tex A&M Eng Exp Stn. 2019. https://hdl.handle.net/1969.1/....

15.

Sobol IM, Kucherenko S. Global sensitivity indices for nonlinear mathematical models. Review. Wilmott. 2005;1:56-61. https://doi.org/10.1002/wilm.4....

16.

Sobol M, Statnikov RB. Selecting optimal parameters in multicriteria problems. Drofa, Moscow 2006.

17.

Sroka Z, Prakash S, Wlostowski R. Design of the turbocharger bearing arrangement to increase the overall efficiency of the combustion engine. Combustion Engines. 2022;188(1):83-89. https://doi.org/10.19206/CE-14....

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.