Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Evaluation of the antiwear properties of timely changed engine oils

1

Chair of Vehicles and Machinery Exploitation, University of Warmia and Mazury in Olsztyn, Poland

Submission date: 2023-05-31

Final revision date: 2023-06-28

Acceptance date: 2023-07-01

Online publication date: 2023-07-24

Publication date: 2023-11-11

Corresponding author

Daria Skonieczna

Chair of Vehicles and Machinery Exploitation, University of Warmia and Mazury in Olsztyn, Oczapowskiego 11, 11-041 Olsztyn, Olsztyn, Poland

Chair of Vehicles and Machinery Exploitation, University of Warmia and Mazury in Olsztyn, Oczapowskiego 11, 11-041 Olsztyn, Olsztyn, Poland

Combustion Engines 2023,195(4), 116-122

KEYWORDS

TOPICS

ABSTRACT

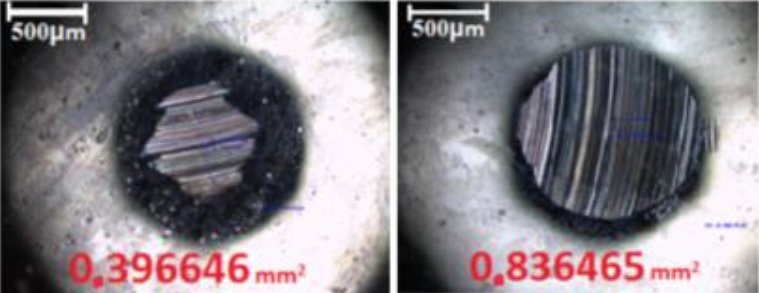

The article presents the results of tests, replaced according to the vehicle manufacturer's recommendations, of engine oils. The sample of engine oils in service came from spark-ignition and compression-ignition vehicles used in urban or mixed mode. During their collection, the type of drive unit, the mileage of the car and the number of kilometres the oil was used for were recorded for each sample (this was the main criterion for differentiating samples). In addition, a control group of samples consisting of fresh oils of the same viscosity grade and distributed by the same producer was set up to observe changes in the parameters of individual lubricants after the operating period. The first part of the empirical study consisted of determining the physico-chemical properties of the lubricants, i.e.: kinematic viscosity, density and water content. The second part involved anti-wear tests using a T-02U tribotester. The use of the tribotester made it possible to record the anti-wear parameter, i.e. moment of friction, and also the load imposed on the friction node, as a result of which it was possible to calculate the friction force and friction coefficient. The research was complemented by an analysis of worn surfaces of the friction node on a microscope. The tests carried out can be used for predictive purposes, in terms of assessing the condition of a lubricant subjected to an operating process in an internal combustion engine.

REFERENCES (24)

1.

ASTM D 4172-94 (Method B) – Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (FourBall Method).

2.

Chmielewski Z. Assessment of the kinetics of changes in selected physicochemical indicators of engine oil in operation. Combustion Engines. 2022;188(1):24-29. https://doi.org/10.19206/CE-14....

3.

EN ISO 12937:2000 Petroleum products – Determination of water – Coulometric Karl Fischer titration method.

4.

EN ISO 20623:2018 Petroleum and related products – Determination of the extreme-pressure and anti-wear properties of fluids – Four ball method (European conditions).

5.

EN ISO 3104:2020 Petroleum products – Transparent and opaque liquids – Determination of kinematic viscosity and calculation of dynamic viscosity.

6.

EN ISO 3675:1998 Crude petroleum and liquid petroleum products – Laboratory determination of density.

7.

Farhanah AN, Bahak MZ. Engine oil wear resistance. Journal Tribologi. 2015;4:10-20. https://jurnaltribologi.mytrib... (accessed on 15.05.2023).

8.

Fatima N, Minami I, Holmgren A, Marklun P, Berglund K, Larsson R. Influence of water on the tribological properties of zinc dialkyl-dithiophosphate and over-based calcium sulphonate additives in wet clutch contacts. Tribol Int. 2015;87:113-120. https://doi.org/10.1016/j.trib....

9.

Ghannam MT, Selim MYE, Khedr MAM, Bin Taleb NAG, Kaalan NR. Investigation of the rheological properties of waste and pure lube oils. Fuel. 2021;298:120774. https://doi.org/10.1016/j.fuel....

10.

Holmberg K, Erdemir A. Influence of tribology on global energy consumption, costs and emissions. Friction. 2017;5:263-284. https://doi.org/10.1007/s40544....

11.

Hu E, Hu X, Liu T, Fang L, Dearn KD, Xu H. The role of soot particles in the tribological behavior of engine lubricating oils. Wear. 2013;304:152-161. https://doi.org/10.1016/j.wear....

12.

Idzior M, Aging of engine oils and their influence on the wear of an internal combustion engine. Combustion Engines. 2021;185(2):15-20. https://doi.org/10.19206/CE-13....

13.

Idzior M, Wichtowska K. Study on the influence of vehicle run on changes of engine oil properties. Autobusy: technika, eksploatacja, systemy transportowe. 2016;17(6):900-904.

14.

Jakóbiec J, Budzik G. Agents influencing degree of engine oil during exploitation. Arch Automot Eng. 2007;3:209-216.

15.

Jędrychowska S. Optimalization of water determination conditions by coulometric titration method with evaporation for lubricating oils. Nafta-Gaz. 2021;7;480-489. https://doi.org/10.18668/NG.20....

16.

Landowski B, Baran M. Analysis of changes in the value of selected lubricant characteristics during use. MATEC Web Conf. 2019;302:01009. https://doi.org/10.1051/matecc....

17.

Landowski B, Baran M. Analysys of selected results of engine oil tests. MATEC Web Conf. 2019;302:01010. https://doi.org/10.1051/matecc....

19.

Ryniewicz A, Bojko Ł, Madej T. Estimation of viscosity engine oils using rotational rheometer. SJSUTST. 2014;83:225-234.

20.

Sejkorová M, Hurtová I, Jilek P, Novák M, Voltr O. Study of the effect of physicochemical degradation and contamination of motor oils on their lubricity. Coatings. 2021;11(1):60. https://doi.org/10.3390/coatin....

21.

Thapliyal P, Thakre GD. Correlation study of physicochemical, rheological and tribological parameters of engine oils. Adv Tribol. 2017:1-12. https://doi.org/10.1155/2017/1....

22.

Zaharia C, Niculescu R, Clenci A, Iorga V. Analyse of used oil in order to emit diagnosis interpretations of the diesel engine operation. Rom J Automot Eng. 2019;25(1):5-11.

23.

Zaharia C, Niculescu R, Iorga-Siman V, Ducu CM. Diagnosing the operation of a locomotive diesel engine based on the analysis of used oil in the period between two technical revisions. Int Cong Automotive and Transport Engineering, Brasov, Romania. 2017. https://doi.org/10.1007/978-3-....

24.

Zaharia C, Niculescu R, Năstase M, Clenci A, Iorga-Simăn V. Engine oil analysis to evaluate the degree of its wear during the period of operation of the vehicle. IOP Conf Series: Materials Science and Engineering. 2022;1220:012037. https://doi.org/10.1088/1757-8....

CITATIONS (2):

1.

Modelling lubricating oil wear using fuzzy logic

Daria Skonieczna, Piotr Szczyglak, Magdalena Lemecha

Combustion Engines

Daria Skonieczna, Piotr Szczyglak, Magdalena Lemecha

Combustion Engines

2.

Synergistic Methodology for Studying the Lubrication Process of Kinematic Nodes

Daria Skonieczna, Oleksandr Vrublevskyi, Piotr Szczyglak, Jerzy Napiórkowski

Journal of Tribology

Daria Skonieczna, Oleksandr Vrublevskyi, Piotr Szczyglak, Jerzy Napiórkowski

Journal of Tribology

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.