Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

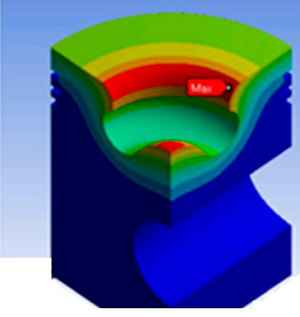

Optimization of the combustion chamber strength of aluminum pistons in diesel engines using the DuralBowl technology

1

Inżyniering, Federal Mogul Gorzyce Sp. z o.o., Poland

Submission date: 2022-06-08

Final revision date: 2022-08-12

Acceptance date: 2022-08-25

Online publication date: 2022-09-02

Publication date: 2023-01-02

Corresponding author

Paweł Kamil Żurawski

Inżyniering, Federal Mogul Gorzyce Sp. z o.o., Odlewników 52, 39-432, Gorzyce, Poland

Inżyniering, Federal Mogul Gorzyce Sp. z o.o., Odlewników 52, 39-432, Gorzyce, Poland

Combustion Engines 2023,192(1), 91-96

KEYWORDS

TOPICS

ABSTRACT

The article focuses on the problem of loading the combustion chamber of diesel engine pistons together with the method of its optimization using the DuralBowl technology. Along with the growing requirements of exhaust emission standards, the increasing competition in the efficiency of internal combustion engines, the load on the combustion pistons increases due to the increase in pressure and temperature of fuel combustion and the tendency to slim the structure. Numerical analyzes and analyzes of damaged pistons in diesel engines have shown that one of the places most exposed to piston damage are the combustion chambers. There is a concentration of thermomechanical stress at the edge of the combustion chamber, which may lead to the destruction of the piston and the necessity to carry out overhaul of the drive unit. One of the technologies that optimizes the strength of this zone is the DuralBowl local remelting process. This process allows for several timesimprovement in the fatigue strength of pistons in internal combustion engines. The article analyzes the thermomechanical load on the combustion chamber along with the impact of this load on the durability of pistons in diesel engines. An analysis of the DuralBowl process was also performed, aimed at eliminating the negative effects of loading the combustion chamber, extending the piston life. The analysis focused on the microstructure of the material before and after the DuralBowl process.

REFERENCES (23)

1.

Walczak M, Bieniaś J, Stradomska B, Jankowski A, Bielecki D. Wear of engine pistons – microstructural characteristics of materials used to produce them. Innovatio Press Wydawnictwo Naukowe Wyższej Szkoły Ekonomii i Innowacji. Lublin 2011;1(1):59-72. https://wydawnictwo.wsei.eu/se....

2.

Merkisz J. Some trends in the evolution of combustion engines. Combustion Engines. 2004;118(1):28-39. https://doi.org/10.19206/CE-11....

3.

Stanik W, Jakóbiec J. Environmentally friendly development of diesel (compression-ignition) engine technologies. Bezpieczeństwo i ekologia. 2012;36(7-8). http://yadda.icm.edu.pl/baztec....

4.

Uczak De Goes W, Somhoorst J, Markocsan N, Gupta M, Ilikova K. Spension plasma-sprayed thermal barrier coatings for light duty diesel. J Therm Spray Tech. 2019;(28):1674-1687. https://link.springer.com/arti....

5.

Siadkowska K, Majczak A, Barański G. Studying a construction of pistons for the aircraft CI engine. Combustion Engines. 2017;168(1):161-167. https://doi.org/10.19206/CE-20....

6.

Mysłowski J, Talaga K. Thermal loads a piston in a diesel engine during startup. Combustion Engines. 2008;133(2): 20-25. https://doi.org/10.19206/CE-11....

7.

Kalke J, Szczeciński M, Mazuro P. Unsteady conjugated heat transfer in cylinder of highly loaded opposed-piston engine. Combustion Engines. 2016;167(4):64-72. https://doi.org/10.19206/CE-20....

8.

Pietrykowski K, Magryta P, Skiba K. Finite element analysis of a composite piston for a diesel aircraft engine. Combustion Engines. 2019;179(4):107-111. https://doi.org/10.19206/CE-20....

9.

Bąkowski H, Stanik Z. Application of the FEM analytical practice for explanation of the effect of service conditions on emergency wear of the self-ignition engine piston. Mechanik. 2010;4(83). http://yadda.icm.edu.pl/baztec....

10.

Noriega Lozano JI, Paredes Rojas JC, Romero Ángeles B, Urriolagoitia Sosa G, Contreras Mendoza BA, Torres San Miguel CR et al. Redesign of a diesel combustion engine to use biodiesel blends. Materials. 2021;14(11):2812. https://doi.org/10.3390/ma1411....

11.

Wróblewski E, Iskra A, Babiak M. Minimizing wear of components piston-cylinder group. Autobusy: technika, eksploatacja, systemy transportowe. 2017;18(16):1137-1141.

12.

Miguel A, Drummond H, Copeland C. Improving heat transfer and reducing mass in a gasoline piston using additive manufacturing. SAE Technical Paper 2015-01-0505. 2015. https://doi.org/10.4271/2015-0....

13.

Ganji PR, Singh RN, Raju VRK, Srinivasa Rao S. Design of piston bowl geometry for better combustion in direct-injection compression ignition engine. Sadhana. 2018;43(92):1-9. https://doi.org/10.1007/s12046....

14.

Paramvir VS, Kumar ST, Singh R, Kumar N. Modification in combustion chamber geometry of ci engines for suitability of biodiesel: A review. Renew Sust Energ Rev. 2017; (79):1016-1033. https://doi.org/10.1016/j.rser....

15.

Ramesh-Bapu BR, Saravanakumar L, Durga-Prasad B. Effects of combustion chamber geometry on combustion characteristics of a DI diesel engine fueled with calophyllum inophyllum methyl ester. J Energy Inst. 2017;90(1):82-100. https://doi.org/10.1016/j.joei....

16.

Vedharaj S, Vallinyagam R, Yang WA, Saravanan CG, Lee PS. Optimisation of combustion bowl geometry for the operation of kapok biodiesel – Diesel blends in a stationary diesel engine. Fuel. 2015;(139):561-567. https://doi.org/10.1016/j.fuel....

17.

Yan B, Wang H, Zheng Z, Qin Y, Yao M. Experimental and numerical investigation of the effects of combustion chamber reentrant level on combustion characteristics and thermal efficiency of stoichiometric operation natural gas engine with EGR. Appl Therm Eng. 2017;(123):1473-1483. https://doi.org/10.1016/j.appl....

18.

Dimitriou P, Wang W, Peng Z. A piston geometry and nozzle spray angle investigation in a di diesel engine by quantifying the air-fuel mixture. Int J Spray Combust. 2015;7(1):1-24. https://doi.org/10.1260/1756-8....

19.

Yaliwal VS, Banapurmath NR, Gireesh NM, Hosmath RS, Donateo T, Tewari PG. Effect of nozzle and combustion chamber geometry on the performance of a diesel engine operated on dual fuel mode using renewable fuels. Renew Energ. 2016;(93):483-501. https://doi.org/10.1016/j.rene....

20.

Dhamak CS, Patil BD, Chavaan N, Dharmashale VR. Piston analysis of IC engine. International Journal of Advance Research and Innovative Ideas in Education. 2015;(2):317-325. http://ijariie.com/AdminUpload....

21.

Piston damage – recognising and rectifying. MS Motorservice International GmbH. 2018. https://mam.ms-motorservice.co...? guid=14c0122387e59c2c (20.05.2022).

22.

Hellstern U. New Mercedes-Benz V6 diesel engines use DuraBowl® piston technology from Federal-Mogul. Cision Distribution. 1.09.2011.

23.

Federal-Mogul introduces new diesel piston design to support downsized engines with higher output. Green Cars Congress Energy, technologies and policies for sustainable mobility. 11.2009. https://www.greencarcongress.c....

CITATIONS (4):

1.

Repair methodology of a piezoelectric injector utilizing components obtained from selective decomposition

Tomasz Stoeck

Combustion Engines

Tomasz Stoeck

Combustion Engines

2.

Assessment of the effectiveness of mounting the aircraft piston combustion engine on a test stand

Grzegorz M. Szymański, Marek Waligórski, Wojciech Misztal

Combustion Engines

Grzegorz M. Szymański, Marek Waligórski, Wojciech Misztal

Combustion Engines

3.

Thermal and structural improvements of a motorcycle piston using a fully coupled thermo-mechanical FEM simulation

Juan Diego Toledo Valera, Anastasios Zavos, Pantelis G Nikolakopoulos

International Journal of Engine Research

Juan Diego Toledo Valera, Anastasios Zavos, Pantelis G Nikolakopoulos

International Journal of Engine Research

4.

Tribological Analysis of Manganese Phosphate Coating on Steel Pistons for Internal Combustion Engines

Paweł Żurawski, Andrzej Trytek

Key Engineering Materials

Paweł Żurawski, Andrzej Trytek

Key Engineering Materials

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.