Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Proper orthogonal decomposition analysis of an atomized fuel spray of marine diesel engine

1

Institute of Naval Architecture, Gdansk University of Technology, Poland

2

Institute of Energy, Gdańsk University of Technology, Poland

3

Institute of Heat Engineering, Warsaw University of Technology, Poland

Submission date: 2025-06-13

Final revision date: 2025-09-04

Acceptance date: 2025-09-08

Online publication date: 2025-09-26

Publication date: 2026-01-14

Corresponding author

Joanna Grochowalska

Institute of Naval Architecture, Gdansk University of Technology, Gdansk, Poland

Institute of Naval Architecture, Gdansk University of Technology, Gdansk, Poland

Combustion Engines 2026,204(1), 167-175

KEYWORDS

TOPICS

ABSTRACT

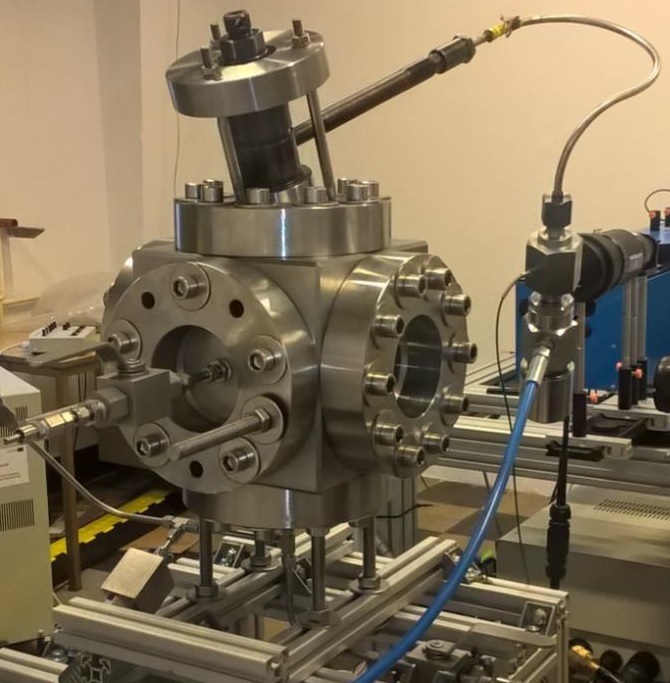

Most marine vessels are powered by diesel engines. Unfortunately, fuel combustion releases harmful toxic compounds into the atmosphere. The International Maritime Organization (IMO) regulates these emissions, making their reduction essential for engineers and scientists. The fuel combustion process in a marine diesel engine's cylinder precedes the fuel spray injection and atomization. Fuel spray's flow fluctuations and vortex structures significantly impact the combustion. This paper presents research using the Mie Scattering optical technique to analyze snapshot sequences of spray patterns recorded with a high-speed camera. These snapshots are the results of experimental research on atomized fuel sprays with a marine diesel engine injector within a constant volume chamber. The influence of different chamber backpressures on the fuel spray is studied. The Proper Orthogonal Decomposition (POD) method is promising for quantitatively analyzing spray structures and flow characteristics. This research demonstrates how different chamber conditions affect the decay of the POD singular values, which typically indicate flow characteristics like coherence and fluctuations.

REFERENCES (23)

1.

Berkooz G, Holmes P, Lumley JL. The proper orthogonal decomposition in the analysis of turbulent flows. Annu Rev Fluid Mech. 1993;25(1):539-575. https://doi.org/10.1146/annure....

2.

Chen H, Hung DL, Xu M, Zhuang H, Yang J. Proper or-thogonal decomposition analysis of fuel spray structure var-iation in a spark-ignition direct-injection optical engine. Exp Fluids. 2014;55:1-12. https://doi.org/10.1007/s00348....

3.

Deng J, Wang X, Wei Z, Wang L, Wang C, Chen Z. A review of NOx and SOx emission reduction technologies for marine diesel engines and the potential evaluation of liquefied natural gas fuelled vessels. Sci Total Environ. 2021;766:144319. https://doi.org/10.1016/j.scit....

4.

Du W, Zhang Q, Zhang Z, Lou J, Bao W. Effects of injec-tion pressure on ignition and combustion characteristics of impinging diesel spray. Appl Energy. 2018;226:1163-1168. https://doi.org/10.1016/j.apen....

5.

Ganti H, Khare P. Data-driven surrogate modeling of multi-phase flows using machine learning techniques. Comput Fluids. 2020;211:104626. https://doi.org/10.1016/j.comp....

6.

Grochowalska J. Analysis of the macrostructure of the fuel spray atomized with marine engine injector. Combustion Engines. 2019;179(4):80-85. https://doi.org/10.19206/CE-20....

7.

Grochowalska J, Jaworski P, Kapusta Ł. Analysis of the structure of the atomized fuel spray with marine diesel en-gine injector in the early stage of injection. Combustion En-gines. 2023;195:97-103. https://doi.org/10.19206/CE-16....

8.

Hu N, Zhou P, Yang J. Reducing emissions by optimising the fuel injector match with the combustion chamber geometry for a marine medium-speed diesel engine. Transp Res D Transp Environ. 2017;53:1-16. https://doi.org/10.1016/j.trd.....

9.

International Maritime Organization. Fourth Greenhouse Gas Study 2020. London: IMO 2020 (accessed on 2025.05.06) https://www.imo.org/en/ourwork....

10.

Kafar L, Merkisz J, Piaseczny L. Fuel spray model in a medium speed marine engine – a simulation. Combustion Engines. 2006;126(3):63-76. https://doi.org/10.19206/CE-11....

11.

Kapitza L, Imberdis O, Bensler HP, Willand J, Thévenin D. An experimental analysis of the turbulent structures generated by the intake port of a DISI-engine. Exp Fluids. 2010;48:265-280. https://doi.org/10.1007/s00348....

12.

Kistler. Piezoresistive high pressure sensor. 2014 (accessed on 2025 May 6). https://www.kistler.com/type=6....

13.

Lewińska J, Kapusta ŁJ. Analysis of the microstructure of the fuel spray atomized by marine injector. Combustion En-gines. 2017;169(2):120-124. https://doi.org/10.19206/CE-20....

14.

Lumley JL. Computational modeling of turbulent flows. Adv Appl Mech. 1979;18:123-176. https://doi.org/10.1016/S0065-....

15.

Ma H, Wu X, Feng F, Wang D, Yang C, Zhuo C. An experimental study on fuel spray-induced vortex-like structures. Exp Therm Fluid Sci. 2014;57:335-343. https://doi.org/10.1016/j.expt....

16.

Najar I, Buchholz B, Stengel B, Fink C, Hassel E. Influence of the fuel properties on the injection process and spray development in a large ship diesel engine. In: ILASS–Europe 2017, 28th Conf on Liquid Atomization and Spray Systems; 2017 Sep 6-8; Valencia, Spain. https://doi.org/10.4995/ILASS2....

17.

Salvador FJ, Gimeno J, De la Morena J, González-Montero LA. Experimental analysis of the injection pressure effect on the near-field structure of liquid fuel sprays. Fuel. 2021;292:120296. https://doi.org/10.1016/j.fuel....

18.

Soid SN, Zainal ZA. Spray and combustion characterization for internal combustion engines using optical measuring techniques – a review. Energy. 2011;36(2):724-741. https://doi.org/10.1016/j.ener....

19.

Viana M, Hammingh P, Colette A, Querol X, Degraeuwe B, de Vlieger I, van Aardenne J. Impact of maritime transport emissions on coastal air quality in Europe. Atmos Environ. 2014;90:96-105. https://doi.org/10.1016/j.atmo....

20.

Weiss J. A tutorial on the proper orthogonal decomposition. In: AIAA Scitech 2019 Forum; 2019 Jan 7-11; San Diego, CA. Reston (VA): AIAA; 2019. Paper No.: AIAA 2019-3333. https://doi.org/10.2514/6.2019....

21.

Wrzask K, Kowalski J, Le VV, Nguyen VG, Cao DN. Fault detection in the marine engine using a support vector data description method. J Mar Eng Technol. 2024;23(6):412-422. https://doi.org/10.1080/204641....

22.

Yao C, Geng P, Yin Z, Hu J, Chen D, Ju Y. Impacts of nozzle geometry on spray combustion of high pressure common rail injectors in a constant volume combustion chamber. Fuel. 2016;179:235-245. ttps://doi.org/10.1016/j.fuel.2016.03.097.

23.

Zhang Z, Zhang P, Chen H, Wu H, Geng L, Zhang W et al. Optical study on the spray and combustion characteristics of diesel-biodiesel-alcohol blend fuels on a constant volume combustion chamber. J Energy Inst. 2024;117:101779. https://doi.org/10.1016/j.joei....

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.