Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Investigation of novel ceramic materials (Al2O3 and SSiC) for high-pressure pumps’ delivery sections

1

Institute of Combustion Engines and Powertrains, Poznan University of Technology, Poland

Submission date: 2023-07-27

Final revision date: 2023-10-13

Acceptance date: 2023-10-19

Online publication date: 2023-11-23

Publication date: 2024-01-02

Corresponding author

Wojciech Karpiuk

Institute of Combustion Engines and Powertrains, Poznan University of Technology, pl. Marii Skłodowskiej Curie 5, 60-965, Poznań, Poland

Institute of Combustion Engines and Powertrains, Poznan University of Technology, pl. Marii Skłodowskiej Curie 5, 60-965, Poznań, Poland

Combustion Engines 2024,196(1), 153-160

KEYWORDS

TOPICS

ABSTRACT

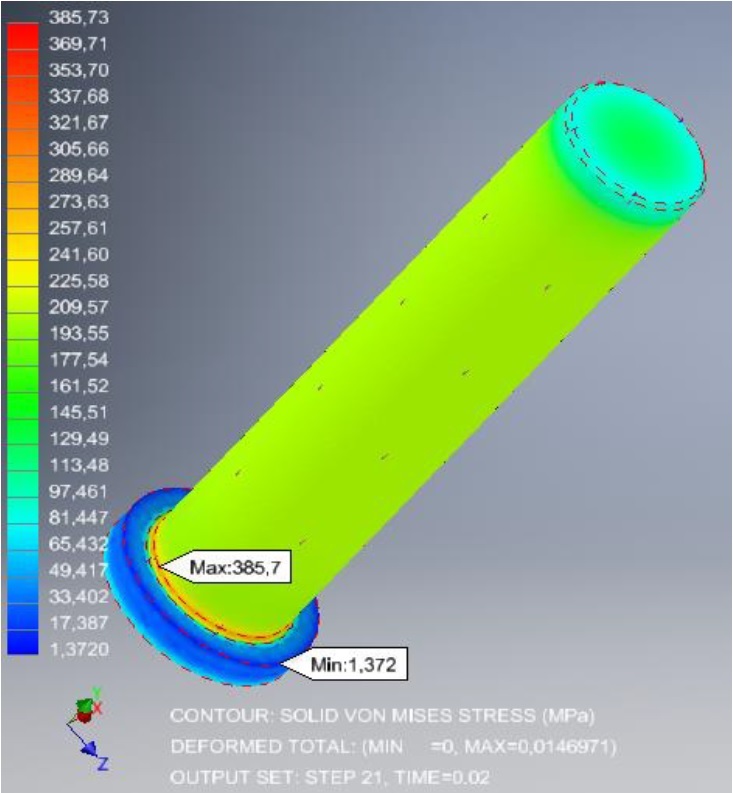

In this paper, a comparative analysis of structural materials used in the construction of high-pressure pumps’ delivery sections was carried out. The focus was on a comparison of the ceramic materials such as corundum (alumina, Al2O3) and silicon carbide (solid-state sintered) – SSiC with bearing alloy steel 100 Cr6, that is the most common material used to make piston and cylinders of the delivery section of common rail injection pumps. Simulations performed using finite element method have proven that ceramic materials have a number of advantages and could therefore be an interesting substitute for materials traditionally used in this area.

REFERENCES (25)

1.

Bajerlein M, Bor M, Karpiuk W, Smolec R, Spadlo M. Strength analysis of critical components of high-pressure fuel pump with hypocycloid drive. B Pol Acad Sci Tech. 2020;68(6):1341-1350. https://doi.org/10.24425/bpast....

2.

Blicharski M. Material engineering (PL original: Inżynieria materiałowa). WNT. Warsaw 2019.

3.

Clifton B. Ultracoatings: Enabling energy and power solutions in high contact stress environments through next-generation nanocoatings. CRADA Final Report 2012.

4.

Dulias U, Zum Gahr K-H. Investigation of Al2O3- and SSiC-ceramic under lubricated, reciprocating sliding contact and cavitation erosion. Materialwiss Werkst. 2005;36(3-4):140-147. https://doi.org/10.1002/mawe.2....

5.

Falkowski H, Krępeć T. Maintenance and repair of diesel engine fuel apparatus. WKiL. Warsaw 1973.

6.

Gancarczyk T, Knefel T. Model analysis of the high pressure pump of a common rail system. Mechanik. 2013;86.

7.

Golewski GL. Stress intensity factor as a basic parameter for assessing the fracture toughness of concrete composites. Drogownictwo. 2010;1:31-35.

8.

Ji R, Yao Z, Zhang Y, Wang R. Effects of nano-ceramic coatings on the thermal structure of ω-type pistons. Chinese Intern Combust Engine Eng. 2023;44(2):51-57. https://doi.org/10.13949/j.cnk....

9.

Kaczorowski M, Krzyńska A. Structural metallic, ceramic and composite materials. 2nd ed. Warsaw Technical University Publishing House. Warsaw 2017.

10.

Karpiuk W. Study of the design of a hypocycloidal injection pump. Poznan University of Technology Publishing House. Poznan 2022.

11.

Kruczyński S, Chrupek B. Malfunctions of the common rail fuel system of modern compression-ignition engines Zeszyty Naukowe Instytutu Pojazdów. Warsaw 2014.

12.

Li R, Chen Q, Ouyang L, Ding Y. Adhesion strength and bonding mechanism of γ-Fe (111)/α-Al2O3 (0001) interfaces with different terminations. J Alloy Compd. 2021;870:159529. https://doi.org/10.1016/j.jall....

13.

Magryta P, Pietrykowski K. Crankshaft geometry modification and strength simulations for a new design of diesel opposed-piston engine. Combustion Engines. 2023;194(3):123-128. https://doi.org/10.19206/CE-16....

14.

Majeed EA, Rashid HK, Hussain MK. Review of ceramic materials that used as a thermal barrier in diesel engine pistons. J Phys Conf Ser. 2021;1973:012125. https://doi.org/10.1088/1742-6....

15.

Matizamhuka WR. Advanced ceramics – the new frontier in modern-day technology: Part I. J S Afr I Min Metall. 2018;118:757-764. https://doi.org/10.17159/2411-....

16.

Mercier JP, Zambelli G, Kurz W. Introduction to Materials Science. Elsevier 2003. https://doi.org/10.1016/C2009-...

17.

Merkisz J, Idzior M, Lijewski P, Fuc P, Karpiuk W. The analysis of the quality of fuel spraying in relation to selected rapeseed oil fuels for the common rail system. Proceedings of the Ninth Asia-Pacific International Symposium on Combustion and Energy Utilization. 2008.

18.

Mohd Tamam MQ, Omi MRT, Yahya WJ, Ithnin AM, Abdul Rahman H, Rahman MM et al. Engine performance and emissions evaluation of surfactant-free B30 biodiesel–diesel/water emulsion as alternative fuel. Sci Rep. 2023;13(1):10599. https://doi.org/10.1038/s41598....

19.

Nie G, Li Y, Sheng P, Zuo F, Wu H, Liu L et al. Microstructure refinement-homogenization and flexural strength improvement of Al2O3 ceramics fabricated by DLP-ste-reolithography integrated with chemical precipitation coating process. J Adv Ceram. 2021;10:790-808. https://doi.org/10.21203/rs.3.....

20.

Niezgoda T, Małachowski J, Szymczyk W. Numerical modelling of the microstructure of ceramics. WNT. Warsaw 2005.

21.

PN-EN 590+A1:2017-06, Automotive fuels – Diesel fuels – Requirements and test methods.

23.

Vengatesan S, Yadav P, Varuvel EG. Effect of alloying elements and ceramic coating on the surface temperature of an aluminum piston in a diesel engine. J Nanomater. 2022;9916742. https://doi.org/10.1155/2022/9....

24.

Your Source for Materials Information. MatWeb. www.matweb.com (accessed on 15.09.2023).

25.

Zhang J, Xiao G, Yi M, Chen Z, Zhang J, Chen H et al. Mechanical properties of ZrB2/SiC/WC ceramic tool materials from room temperature to 1100°C and cutting performance. Int J Refract Hard Met. 2021;101:1-7. https://doi.org/10.1016/j.ijrm....

CITATIONS (2):

1.

Lumped Parameter Modelling of Common Rail High-Pressure Fuel Injection Pump

O Chiavola, F Palmieri, F Verdoliva

Journal of Physics: Conference Series

O Chiavola, F Palmieri, F Verdoliva

Journal of Physics: Conference Series

2.

Simulation research of the feasibility of developing a multi-fuel valved pulsejet engine

Grzegorz M. Szymański, Bogdan Wyrwas, Mikołaj Klekowicki, Klaudia Strugarek, Malwina Nowak, Aleksander Ludwiczak, Alicja Szymańska

Combustion Engines

Grzegorz M. Szymański, Bogdan Wyrwas, Mikołaj Klekowicki, Klaudia Strugarek, Malwina Nowak, Aleksander Ludwiczak, Alicja Szymańska

Combustion Engines

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.